فائبر پیچ پینل کا استعمال کیسے کریں؟

فائبر پیچ پینلز(ریک اینڈ انکلوژرز مینوفیکچررز - چائنا ریک اینڈ انکلوژرز فیکٹری اینڈ سپلائرز (raisefiber.com) ہائی ڈینسٹی کیبلنگ سسٹمز کے لیے ضروری ہیں، نیٹ ورک کی تعیناتی کے لیے انہیں کیسے استعمال کیا جائے؟ اس سیکشن میں، پیچ پینلز کو فائبر آپٹک سے جوڑنے کے لیے عام اقدامات کیبلز یا نیٹ ورک سوئچز کا مظاہرہ کیا جائے گا۔

فائبر کیبلز کے ساتھ فائبر پیچ پینل کو کیسے جوڑیں؟

سب سے پہلے، یقینی بنائیں کہ آپ کا فائبر پیچ پینل عام طور پر کام کرتا ہے اور اسے صاف اور سطحی کام کی سطح یا میز پر رکھیں۔اگر آپ مکمل طور پر بھری ہوئی فائبر پیچ پینل کا انتخاب کرتے ہیں، تو اسے مخصوص ٹولز کے ساتھ اپنے ریک پر انسٹال کریں۔اگر آپ کا پیچ پینل اتارا گیا ہے، تو براہ کرم اس میں فائبر اڈاپٹر پینل یا کیسٹ ڈالیں۔پھر بڑھتے ہوئے پلیٹ کو صحیح پوزیشن میں ٹھیک کریں۔

کافی فائبر یا کاپر کیبلز تیار کریں جس کی آپ کو ضرورت ہے، گلٹی کو ٹھیک کرکے کیبلز کو جوڑیں اور اضافی فائبر (یا کاپر کیبلز) کو اسپول پر رول کریں۔اس کے بعد، حفاظتی ٹوپی کو ہٹا دیں اور اڈاپٹر میں پوزیشن میں داخل کریں.ایک بار جب تمام کیبلز منسلک ہو جائیں، تو بہتر ہے کہ کیبلز کو بنڈل میں محفوظ کرنے کے لیے زپ ٹائی کا استعمال کریں۔

فائبر آپٹک پیچ پینل پر ہر جیک کے مقام پر لیبل لگائیں تاکہ کیبلز کو الگ کیا جا سکے۔آخر میں، پیچ پینل کو ریک یا کیبنٹ میں لگائیں۔

ایتھرنیٹ پیچ پینل اور نیٹ ورک سوئچ کیسے انسٹال کریں؟

مرحلہ 1: وائرنگ الماری میں 24 پورٹ پیچ پینل اور 24 پورٹ سوئچ کو ریک پر لگے ہوئے فرش اسٹینڈ سے منسلک کریں۔

مرحلہ 2: ایتھرنیٹ کیبلز کو کمپیوٹر روم میں ان کے جیک مقامات سے چلائیں۔ہر تانبے کی کیبل دیوار میں نصب جیک سے آئے گی جسے انسٹالر نے دیوار میں رکھا ہے۔وہ سب تاروں کو ایڈجسٹ کرنے کے لیے ایک چھوٹے سے سوراخ کے ذریعے وائرنگ کی الماری میں واپس آجائیں گے۔

مرحلہ 3: تاروں کو 24 پورٹ پیچ پینل میں جوڑیں اور تاروں کو پیچ پینل پر مناسب سلاٹ سے جوڑنے کے لیے پنچ ڈاؤن ٹول استعمال کریں۔ایک بار تمام تاریں جڑ جانے کے بعد، پلاسٹک کی زپ ٹائیوں کا استعمال کرکے تاروں کو بنڈل میں محفوظ کرنا بہتر ہے۔

مرحلہ 4: ہر جیک کے مقام کو 24 پورٹ پیچ پینل پر لیبل لگائیں تاکہ یہ معلوم ہو سکے کہ کون سا کمرہ اس جیک سے منسلک ہے۔

کیسےbuy فائبر پیچ پینل؟

اس میں ہم نے کے استعمالات کو جانا ہے۔فائبر آپٹک پیچ پینل(Rack & Enclosures Manufacturers - China Rack & Enclosures Factory & Suppliers (raisefiber.com))، یہاں ایک اور سوال آتا ہے – صحیح آپٹک پیچ پینل کا انتخاب کرتے وقت ہمیں کس چیز پر غور کرنا چاہیے؟یہاں وہ ضروری پہلو ہیں:

فائبر پیچ پینل کا سائز

سب سے پہلے، آپ کو فائبر پیچ پینلز پر اپنی ضروریات کو جاننا ہوگا۔اونچائی، گہرائی، چوڑائی اور وزن جیسے بنیادی پیرامیٹرز آپ کے فائبر آپٹک پینلز کی قسم کا تعین کریں گے۔عام طور پر، آپٹک پیچ پینل کا سائز RU یا U سے ماپا جاتا ہے: یہ ریک/دیوار پر نصب آلات کی اونچائی کو بیان کرتا ہے۔1RU، 2RU اور 4RU فائبر پیچ پینلز زیادہ کثافت والے ایپلی کیشنز کے لیے لگائے جاتے ہیں۔اس بات سے کوئی فرق نہیں پڑتا ہے کہ آپ کس قسم کے سائز کے پیچ پینل کا انتخاب کرتے ہیں، براہ کرم اپنے موجودہ آلات اور مستقبل کی ترقی کو پورا کرنے کے لیے ہمیشہ بڑا سائز منتخب کریں۔

فائبر پیچ پینل پورٹ کثافت

سائز کے علاوہ، فائبر پیچ پینلز کی بندرگاہ کی کثافت بھی انتخاب میں ایک اہم حصہ بناتی ہے۔ڈیٹا سینٹرز میں کثافت کی درخواست کبھی کم نہیں ہوگی، اس لیے آپٹیکل پیچ پینل بھی مانگ کو پورا کرنے کے لیے تیار ہوتا ہے۔ایک عام 1U فائبر انکلوژر 48 پورٹس (144 ریشے) تک رکھ سکتا ہے جبکہ ایک اعلی کثافت والا ورژن 96 پورٹس تک کو سپورٹ کرتا ہے۔MPO/MTP کیبلنگ نیٹ ورکس کے لیے، الٹرا ہائی ڈینسٹی پیچ پینلز ہیں جو 1U سائز میں 144 پورٹس کو فعال کرتے ہیں۔مزید برآں، 2U یا 4U سائز والے فائبر پیچ پینلز بھی زیادہ بندرگاہ کی کثافت حاصل کرنے میں مدد کر سکتے ہیں۔

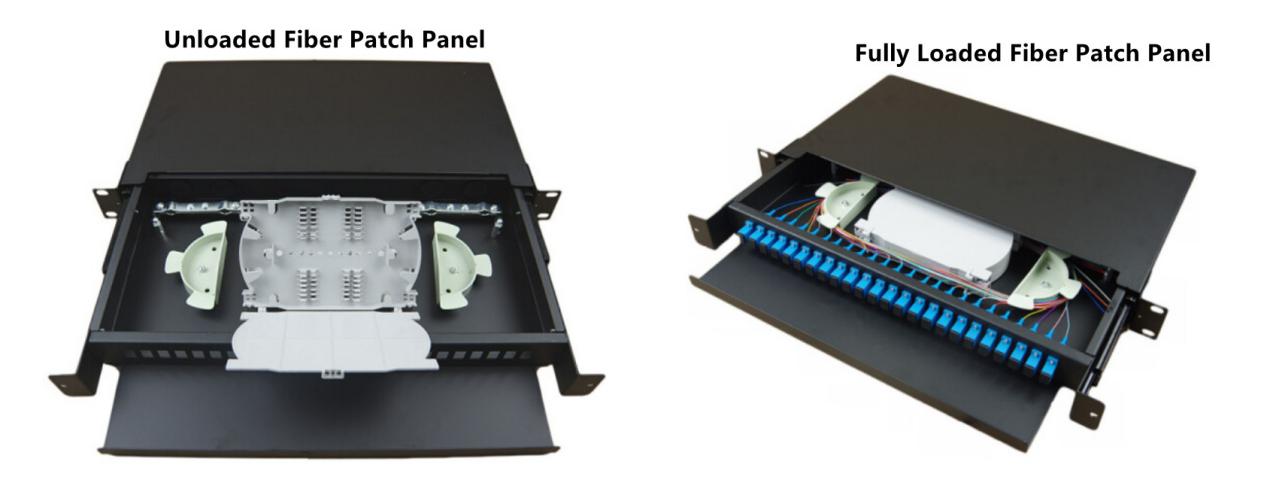

بھری ہوئی یا اتاری ہوئی فائبر پیچ پینل

بھری ہوئی فائبر آپٹک پیچ پینل فائبر اڈاپٹر پینلز یا کیسٹوں کے ساتھ پہلے سے نصب ہے جبکہ ان لوڈ شدہ پیچ پینل خالی ہے۔LC اور MTP کیسٹس کو اکثر بھری ہوئی پیچ پینلز میں نصب کیا جاتا ہے تاکہ 40/100G منتقلی کا راستہ بنایا جا سکے، اس طرح تنصیب پر خرچ ہونے والے وقت کو بہت کم کیا جا سکتا ہے۔تاہم، بھاری بھرکم پینل اکثر مستقل طور پر نصب کیے جاتے ہیں، لہذا اگر بندرگاہوں میں سے ایک کو نقصان پہنچتا ہے تو یہ ہمیشہ کے لیے مردہ ہو جاتا ہے۔جہاں تک ان لوڈ شدہ فائبر پیچ پینلز کا تعلق ہے، آپ تانبے اور فائبر کیبلنگ کو ایڈجسٹ کرنے کے لیے اس پر ملٹی میڈیا فائبر اڈاپٹر پینل لگا سکتے ہیں، اور کسی بھی وقت خراب بندرگاہوں کو تبدیل کر سکتے ہیں۔لیکن آپ کو اڈاپٹر پینل خریدنے کے لیے اضافی رقم اور انسٹال کرنے کے لیے زیادہ وقت خرچ کرنا پڑ سکتا ہے۔

فائبر پیچ پینل کی مطابقت

فائبر پیچ پینل(Rack & Enclosures Manufacturers - China Rack & Enclosures Factory & Suppliers (raisefiber.com)) مطابقت بنیادی طور پر فائبر آپٹک آلات اور اجزاء کے ذریعے طے کی جاتی ہے جن کو پیچ پینل کے ذریعے آپٹیکل کنیکٹیویٹی کی ضرورت ہوتی ہے۔عام ڈوپلیکس سنگل موڈ یا ملٹی موڈ آپٹیکل لنکس کو UPC یا APC قسم کے LC یا SC کنیکٹرز کی ضرورت ہوتی ہے۔تاہم، اگلی نسل کے 40G اور 100G نیٹ ورکنگ اور زیادہ جدید ملٹی فائبر کنیکٹرز اور پلگ ایبل آلات (جیسے QSFP+) کے استعمال کی وجہ سے، فائبر پیچ پینل کا ڈیزائن اور ترتیب مخصوص قطبی تقاضوں کا تقاضا کر سکتا ہے۔براہ کرم اپنی مختلف ضروریات کے لیے اچھی مطابقت کے ساتھ پیچ پینل کا انتخاب کرنا یاد رکھیں۔

نیچے کی لکیر

جدید ڈیٹا سینٹرز کے لیے، فائبر آپٹک پینلز کے ساتھ منظم رہنا ضروری ہے - نہ صرف آسان اپ گریڈ اور فوری رسائی کے لیے، بلکہ ان خطرات کو روکنے کے لیے بھی جو کسی بھی نیٹ ورک سسٹم میں شامل ہیں۔جب آپ اپنے نیٹ ورک کے لیے پیچ پینل کا انتخاب کر رہے ہیں، تو براہ کرم ہمیشہ اپنے بجٹ کے اندر بڑی صلاحیت، زیادہ بندرگاہ کی کثافت، بہترین مطابقت کے ساتھ ایک کو منتخب کرنا یاد رکھیں۔

پوسٹ ٹائم: اکتوبر 09-2022